Mile Square Health Center

Chicago, Illinois USA

Project Overview / Detail

Mile Square Health Center is the first qualified health center with urgent and specialty care under one roof. The Health Center is also the gateway to the University of Illinois (UI) Health campus. The architecture of the center had to reflect Mile Square and UI’s commitment to progress and outstanding service.

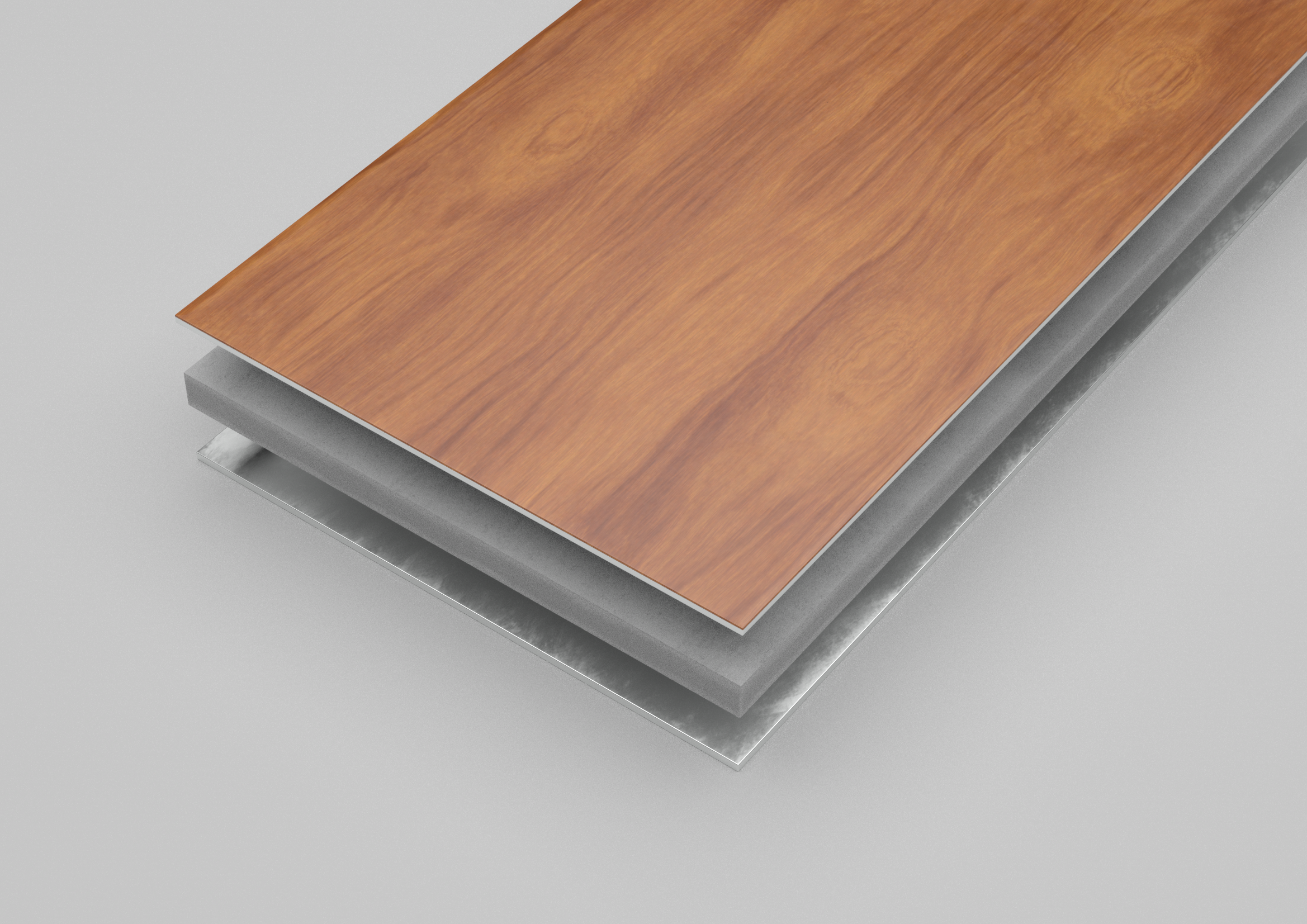

The state-of-the-art medical facility has a stunning mosaic façade. The design communicates the concept of movement, progress and technology. It reflects the dynamic nature of the campus and immediate surroundings. The envelope features Reynobond® 4mm FR Composite Material and a Kawneer curtain wall, meeting architectural and structural requirements and aesthetic-finish quality and panel flatness.

A subtle variation in the tone of grey was required for the exterior of the building. An Anodic Clear Colorweld® 500 paint coating was chosen as the base paint color. The team then introduced two custom colors: MP2, which is 15% darker than the standard Anodic Clear color. Then MP3, which is 75% darker than the standard Anodic Clear color. To ensure that the metal panel joint lines would align with the mullions on the curtain wall and to avoid adding panel joints in corner areas, Reynobond® Composite Material was purchased in 260-inch sheets.

The mosaic pattern continues from the metal panels to the curtain wall. Glass panels align with the metal panels and match in size. The dynamic composition-colored and spandrel glass is reflective and patterned during the day and transparent at night.

The state-of-the-art medical facility has a stunning mosaic façade. The design communicates the concept of movement, progress and technology. It reflects the dynamic nature of the campus and immediate surroundings. The envelope features Reynobond® 4mm FR Composite Material and a Kawneer curtain wall, meeting architectural and structural requirements and aesthetic-finish quality and panel flatness.

A subtle variation in the tone of grey was required for the exterior of the building. An Anodic Clear Colorweld® 500 paint coating was chosen as the base paint color. The team then introduced two custom colors: MP2, which is 15% darker than the standard Anodic Clear color. Then MP3, which is 75% darker than the standard Anodic Clear color. To ensure that the metal panel joint lines would align with the mullions on the curtain wall and to avoid adding panel joints in corner areas, Reynobond® Composite Material was purchased in 260-inch sheets.

The mosaic pattern continues from the metal panels to the curtain wall. Glass panels align with the metal panels and match in size. The dynamic composition-colored and spandrel glass is reflective and patterned during the day and transparent at night.

ARCHITECT

GC

FABRICATOR/INSTALLER

PRODUCT

GC

FABRICATOR/INSTALLER

PRODUCT

Moody Nolan

The George Sollitt Construction Company

SHApe Architectural

Reynobond® 4mm FR Composite Material

The George Sollitt Construction Company

SHApe Architectural

Reynobond® 4mm FR Composite Material

QUANTITY

COLOR

COATING

APPLICATION

CERTIFICATION

COLOR

COATING

APPLICATION

CERTIFICATION

42,600

Anodic Clear / 2 Custom Anodic Clear

Colorweld® 500 / Colorweld® 500 +15% / +75%

Rainscreen System

Leadership in Energy & Environmental Design™ LEED Gold®

Anodic Clear / 2 Custom Anodic Clear

Colorweld® 500 / Colorweld® 500 +15% / +75%

Rainscreen System

Leadership in Energy & Environmental Design™ LEED Gold®

For more information about this project download the full case study PDF

Support & Training

Explore our resources and find all the information you need to make your next project a success.

Download technical documentation and testing reports and learn more about our competitive warranties.

Download technical documentation and testing reports and learn more about our competitive warranties.

Products

Our portfolio of products include Reynobond® Composite Material, Reynoplate® 3mm Solid Aluminum Plate, Reynoclad® Pre-Painted Aluminum Sheets and Reynodual® 3mm Bonded Sheets. All our products support ambitious architectural design and deliver superior performance and protection. Efficient, cost-effective and sustainable, aluminum sheets offer maximum design flexibility and meet the specification requirements of most applications.