Duke Energy Center

Charlotte, North Carolina USA

Project Overview / Detail

The Duke Energy Center is the physical representation of the energy giant’s commitment to the environment. The crystalline 50-story tower is the first LEED Platinum® office building in the country. It has a distinct, sculptural roofline with a handle-shaped bridge at the crown and faceted truncated corners.

As the centerpiece of downtown, the multi-use tower is part of a cultural complex. The complex features three museums and a performing arts center, all small in comparison. The Duke Energy Center desired detail at ground level to complement its surroundings.

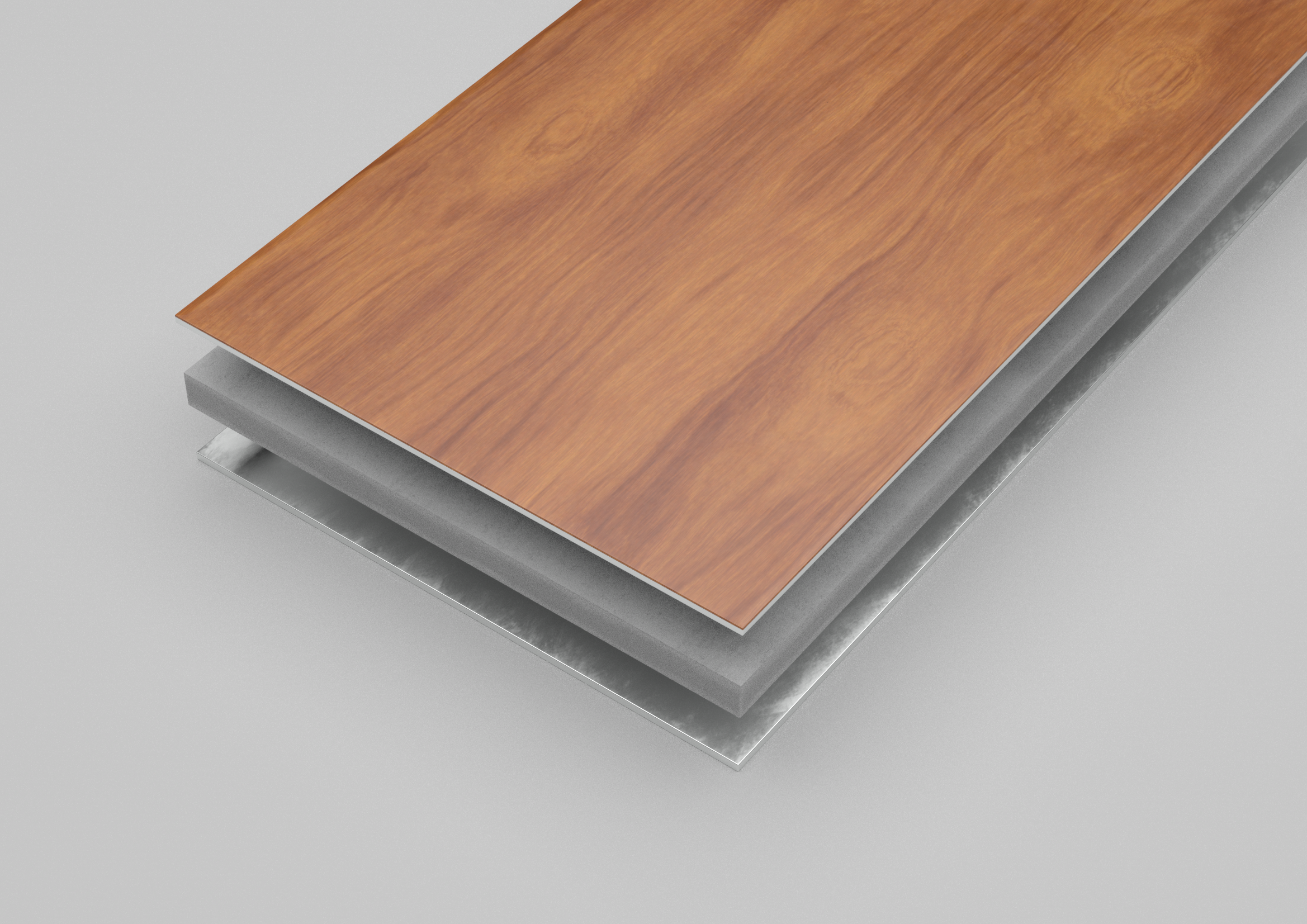

To trim the visual weight of the 1,500,000-square-foot tower, architects specified a building envelope of Reynobond® Composite Material and spandrel and vision glass. The Reynobond® 4mm FR Composite Material—specified with a neutral palette of Colorweld® 300XL Pearl White that was paired with white Brazilian granite and stainless steel accents—were used for corner details, exterior colonnades, recessed entry portals and the tapered crown at the roof, to define and balance the building.

Reynobond® Composite Material takes on a prominent role at the 48th story, where the glass walls slope inward toward the crown. The building corners rise into the air beyond the angular glass façade and reconnect through a metallic bridge that forms a sweeping horizontal sky window. The panels at the crown were challenging to fabricate due to their design. The design features a bond pattern that slopes downward toward a rainwater collection point.

Reynobond® Composite Material’s rigid construction, lightweight, high strength-to-weight ratio and superior flatness were instrumental in the installation. Access to the crown was limited by the geometry of the building. The unique sculpture at the crown could only be accomplished with metal. The flexibility of Reynobond® Composite Material allowed for experimental geometry to achieve the desired effect.

As the centerpiece of downtown, the multi-use tower is part of a cultural complex. The complex features three museums and a performing arts center, all small in comparison. The Duke Energy Center desired detail at ground level to complement its surroundings.

To trim the visual weight of the 1,500,000-square-foot tower, architects specified a building envelope of Reynobond® Composite Material and spandrel and vision glass. The Reynobond® 4mm FR Composite Material—specified with a neutral palette of Colorweld® 300XL Pearl White that was paired with white Brazilian granite and stainless steel accents—were used for corner details, exterior colonnades, recessed entry portals and the tapered crown at the roof, to define and balance the building.

Reynobond® Composite Material takes on a prominent role at the 48th story, where the glass walls slope inward toward the crown. The building corners rise into the air beyond the angular glass façade and reconnect through a metallic bridge that forms a sweeping horizontal sky window. The panels at the crown were challenging to fabricate due to their design. The design features a bond pattern that slopes downward toward a rainwater collection point.

Reynobond® Composite Material’s rigid construction, lightweight, high strength-to-weight ratio and superior flatness were instrumental in the installation. Access to the crown was limited by the geometry of the building. The unique sculpture at the crown could only be accomplished with metal. The flexibility of Reynobond® Composite Material allowed for experimental geometry to achieve the desired effect.

ARCHITECT

GC

FABRICATOR/INSTALLER

PRODUCT

GC

FABRICATOR/INSTALLER

PRODUCT

Tvs design of Atlanta, GA

Batson-Cook Construction of Atlanta, GA

Miller-Clapperton Partnership, Inc., of Austell, GA

Juba Aluminum Products of Concord, NC

Reynobond® 4mm FR Composite Material

Batson-Cook Construction of Atlanta, GA

Miller-Clapperton Partnership, Inc., of Austell, GA

Juba Aluminum Products of Concord, NC

Reynobond® 4mm FR Composite Material

QUANTITY

COLOR

COATING

APPLICATION

CERTIFICATION

COLOR

COATING

APPLICATION

CERTIFICATION

127,000

Pearl White

Colorweld® 300XL

Back-Ventilate Rainscreen System & Exposed Sealant Attachment System

LEED® Platinum

Pearl White

Colorweld® 300XL

Back-Ventilate Rainscreen System & Exposed Sealant Attachment System

LEED® Platinum

For more information about this project download the full case study PDF

Support & Training

Explore our resources and find all the information you need to make your next project a success.

Download technical documentation and testing reports and learn more about our competitive warranties.

Download technical documentation and testing reports and learn more about our competitive warranties.

Products

Our portfolio of products include Reynobond® Composite Material, Reynoplate® 3mm Solid Aluminum Plate, Reynoclad® Pre-Painted Aluminum Sheets and Reynodual® 3mm Bonded Sheets. All our products support ambitious architectural design and deliver superior performance and protection. Efficient, cost-effective and sustainable, aluminum sheets offer maximum design flexibility and meet the specification requirements of most applications.